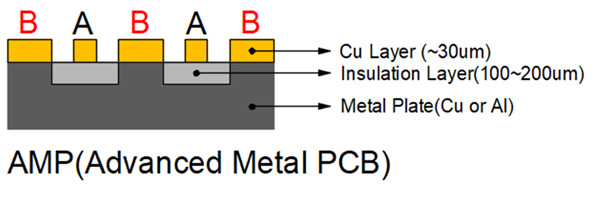

Radiant Heat PCB(AMP)

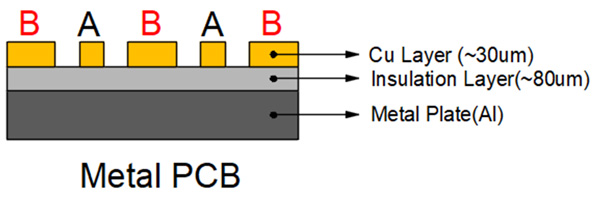

Exothermic devices are manufactured using a metal PCB currently. However, the metal PCB basically has the insulating layer between

the copper layer and the base metal, which reduces the thermal conductivity.

We have developed a product that maximizes the heat dissipation performance by forming the metal directly from the heat transfer path instead of the insulation layer,

thereby solving the difficulties caused by the heat dissipation of the customers.

Comparison with metal PCB

B part: Cu No electricity part since it is heat conduction line.

Features

1) By forming a direct heat transfer path in the heat dissipation element, the heat dissipation performance is realized that is close to the metal heat conduction performance.2) Optimum heat dissipation performance can be achieved by the structure that the PCB itself can perform the heat dissipation function except the only insulation areas where electrical insulation is required in the metal plate.

3) By maximizing the heat dissipation performance, it is possible to extend the lifetime of the heat dissipation element compared with general metal PCB.

4) SMT is possible even though it has excellent heat dissipation.

5) Excellent heat dissipation performance makes it possible to miniaturize the product

6) For example, in case of an LED device with high light efficiency due to heat dissipation, it is possible to improve the heat dissipation performance, thereby prolonging the life of the LED or decreasing the LED quantity in case of the same light efficiency.

Actual Applications